Mistakes to Avoid While Maintaining the Reciprocating Chillers

Reciprocating chillers are a refrigeration system used in HVAC systems. It is used to regulate the temperature of a given space or a heavy-duty machine by compressing the refrigerant gas. They are used in many commercial and residential areas to make the surrounding environment comfortable. However, just like any other machine, the performance and lifespan of the reciprocating chiller totally depend on the maintenance. It can maintain inefficiency, high energy bills, and constant breakdowns, but for that, maintenance is a must.

Tips To Keep in Mind While Maintaining the Reciprocating Chiller

-

Ignoring Regular Maintenance:

One of the biggest mistakes you can make is neglecting the regular maintenance of the cooling solution. The reciprocating machine needs regular inspection and cleaning. If the maintenance part can be skipped, dirt buildup and lubrication issues further worsen its condition. So, you need to set a preventive maintenance schedule. Go for monthly, quarterly, and yearly checkups of the components like filters, compressors, or electrical systems. When conducting the inspection, document the date and timing to track performance and identify potential issues.

-

Using the Wrong Kind of Refrigerant:

Using the wrong kind of refrigerant or overcharging/undercharging the system is common. It can become an expensive error impacting the efficiency of the chiller. It can also damage the compressor. It can also reduce the lifespan of the equipment, and you do not want that to happen. Always go through the manufacturer’s manual to get the right refrigerant. Also, ensure that the lubricants and seals are compatible with the refrigerant.

-

Lubrication & Oil Quality:

The kind of lubrication that you are using also matters. It is the major part of the reciprocating chiller. Infrequent oil changes can result in friction, overheating, and premature wearing of parts. The contamination from moisture and debris can also degrade the oil quality, which will lead to failure of the machine. Here are some of the signs that oil quality is deteriorating. The oil color and viscosity will change. Always inspect the oil condition for any contaminants and degradation. Replace the oil filters and also use the lubricants recommended by the manufacturers.

-

Avoiding Condenser Condition:

The condenser and evaporator coil are important components of the machine. They play an important role in heat transfer, and thus, they should be in good condition. Dust and build-up on the surface of the insulators reduce the efficiency and increase the operational cost.

Inspection and maintenance will keep the condenser in good condition. Schedule the regular cleaning of coils and tubes. For the water-cooled system, ensure proper water treatment to avoid corrosion. On the other hand, for the air-cooled system, clean the filters regularly, especially in a dusty environment.

-

Unusual Noises:

A reciprocating chiller may produce some vibrations due to the movement of the pistons, but if these vibrations turn into weird noises, then it should not be ignored. It can be a sign of underlying issues like loose bolts, bearings, broken valves, cracked pipes, and misaligned components.

So, what you should do is investigate the abnormal sounds. The vibration analysis tool identifies and addresses the imbalance, misalignment, or mechanical looseness. The early detection will help save wastage of money on repair and replacement.

-

Improper Electric Maintenance:

For the reciprocating chiller to function properly, it needs stable electrical power. Overloaded circuits, corroded terminals, and loose connections can cause inefficiency and even damage the sensitive internal components. So never ignore the control panel cleaning, neglecting the sensor board calibration, and skipping the insulation resistance testing.

So, it is vital to check all the electrical connections regularly. Test the sensors, relays, and contacts for efficiency. The faulty parts should be removed immediately so that the operations are smooth.

-

Not Monitoring the Operating Parameters:

Many of the technicians do not understand that regular inspection of the chiller is a must, even though it is working fine. Some of the components, like suction pressure, discharge pressure, and oil temperature, reveal a lot about the machine’s health. So, implement a monitoring record by keeping a close eye on all the components mentioned above. Some of the issues, like refrigerant leaks, valve issues, and declining compressor performance, are signs of problems. If you want to remove the headache of having to manually check the reciprocating chiller, then go for the modern models with an in-built monitoring system. It will alert you in case the machine is not performing up to mark.

End Note…

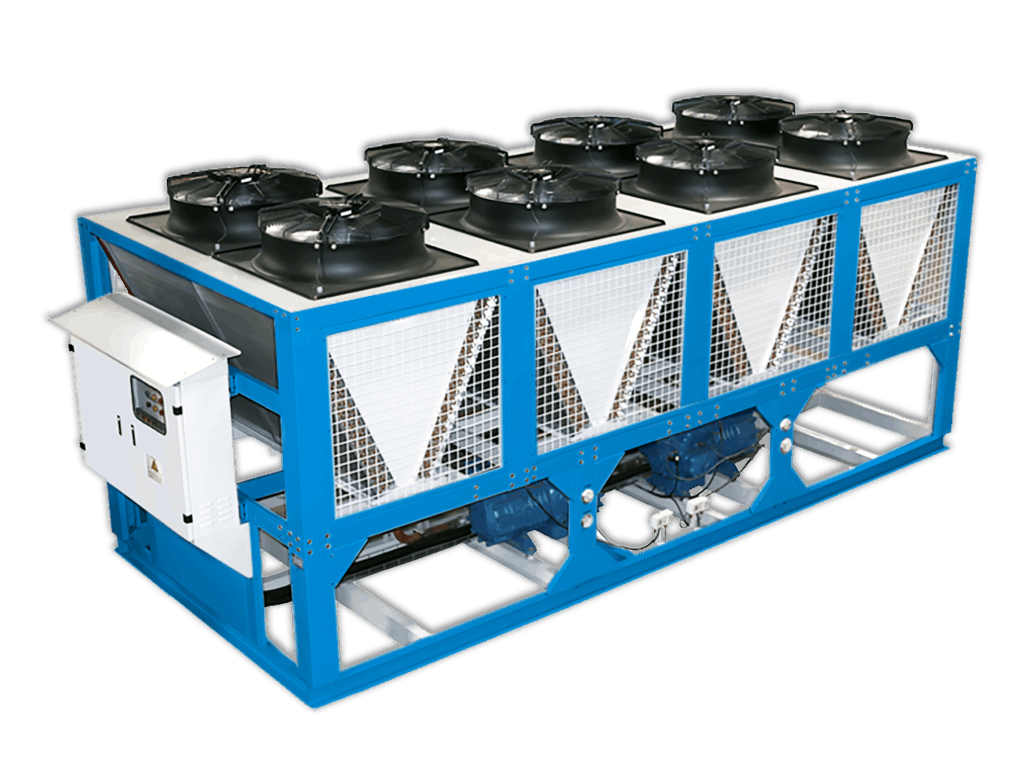

Maintaining the reciprocating chiller is not a tough job, and you can do it all by yourself if you are aware. Hopefully, this post was of great help. ‘Coolstar India’ has the most innovative design of reciprocating chillers, which are ideal for both industrial as well as commercial use. They are designed for high performance and low energy consumption, which leads to efficient removal of the heat from the surrounding area. The operations will be smooth even when there is too much load on the system; such is the reliability of the cooling system.

Frequently Asked Questions

-

How do the Reciprocating Chillers Work?

The chiller works by compressing the refrigeration gas. This gas is cooled in the condenser, expanded through the expansion valve, and finally, it is evaporated in the evaporator to absorb heat from the process water. This cycle continues to repeat in order to achieve the desired temperature.

-

What are the Main Components Of the Reciprocating Chiller?

-

Compressor: It is the heart of the system, compressing the refrigerant gas.

-

Condenser: It removes the heat from the refrigerant.

-

Expansion Valve: It regulates the refrigerant flow and also reduces the pressure.

-

Sensor: It is for monitoring the pressure and safety parameters.

-

What are the Benefits of the Reciprocating Chillers?

-

Easy maintenance

-

Ergonomic design

-

Portable

-

High efficiency

-

Cost-effective operations